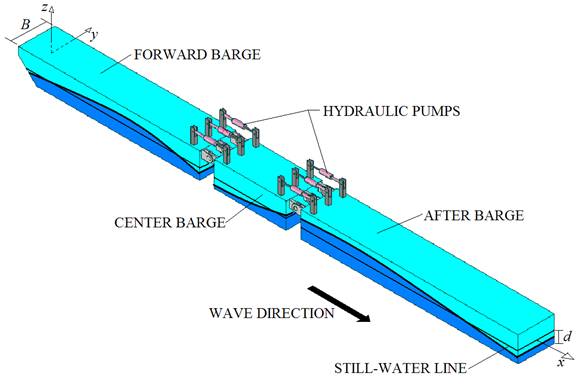

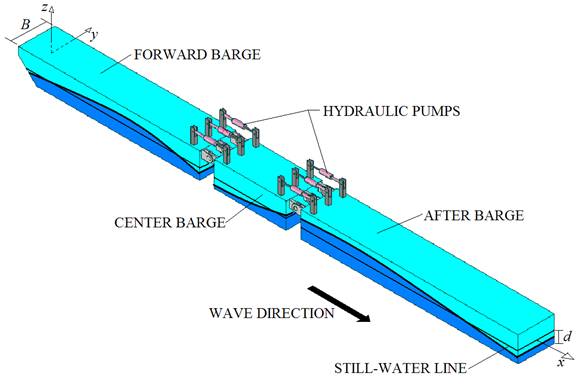

In order to convert saline water into potable water, the saline water must go through a process known as desalinization. Desalination removes the salt and hence, makes the water fit for human and animal consumption as well as agricultural applications. The AWECS converts ocean wave energy into a high-pressure, high-volume hydraulic energy through the pumping action of its on-board (proprietary) seawater pumps actuated by ocean wave energy. The articulated barge system (see attached picture) pre-filters saline water and delivers 1000 psi salt water to a reverse-osmosis (RO) system, wherein salt is extracted. In the RO process, the pressurized seawater is forced through a semi-permeable membrane – completing the desalinization and making potable drinking water. The advantage of the AWECS system is its ability to be energy efficient through the use of the oceans own wave energy to produce a near-inexhaustible supply of potable water. The world’s abundant supply of saline water is thus able to help quench thirsts and irrigate crops for the billion people in need. The AWECS can be deployed anywhere on the planet where there is sufficient ocean wave energy to actuate the process. AWECS, when in mature production, can produce 150,000 gallons/day of potable water at shore side.

The capacity is based on a single AWEC floating system. By deploying several AWEC systems for an application, the production multiplier is established. The incident wave energy that the articulated-barge absorbs is in a crest width that is equal to or wider than the width of the device. That is, the AWEC system radiates waves which interfere with the incident waves and cause a wave-energy focusing upon the device. The energy of the wave is proportional to the product of the wave height squared and wave period. The articulation of the barges, compress the salt water drawn into the cylinders between the barges. These, in turn, compress the intake water to approximately 1000 psi. At the wave passes the AWECS, the wave height is attenuated, reducing the wave energy that is transmitted past the barge.

The design sea conditions are a 1.5 meter wave height and 7.5 second wave period, which are approximately the average wave properties in the mid-Atlantic coastal waters of the contiguous United States.

The capacity is based on a single AWEC floating system. By deploying several AWEC systems for an application, the production multiplier is established. The incident wave energy that the articulated-barge absorbs is in a crest width that is equal to or wider than the width of the device. That is, the AWEC system radiates waves which interfere with the incident waves and cause a wave-energy focusing upon the device. The energy of the wave is proportional to the product of the wave height squared and wave period. The articulation of the barges, compress the salt water drawn into the cylinders between the barges. These, in turn, compress the intake water to approximately 1000 psi. At the wave passes the AWECS, the wave height is attenuated, reducing the wave energy that is transmitted past the barge.

Figure 1.

The barge dimensions are 130 feet long, 20 feet wide and 7 feet in height. The total displacement of the barge is estimated at 50 tons. It is estimated that there is approximately 40 tons of steel in the manufacture of the barge system.

The design sea conditions are a 1.5 meter wave height and 7.5 second wave period, which are approximately the average wave properties in the mid-Atlantic coastal waters of the contiguous United States.